Peco

PECO

Austell, Georgia

My Stars and Garters!

Aluminum Christmas trees made in the south?

Darlings, yes.

PECO promotional image courtesy of Joe Warren.

Aluminum Lovers, welcome to PECO! Short for Production Engineering Company, this manufacturer produced a limited product line of the highest quality aluminum trees in little old Austell, Georgia, just a hop and a skip from Atlanta. PECO (pronounced pee-co) holds the distinction of being the southernmost manufacturer of aluminum trees!

The Company

PECO made a solidly built tree that was beautiful, uncomplicated, and made to last. PECO trees were available in silver, solid green, silver-green, and silver-gold. The only taper trees made by PECO were the later-issued vinyl and bottle-brush trees.

Before the aluminum tree craze, PECO was a well-established manufacturer of aluminum camping furniture, such as the webbed aluminum chairs that everyone had at the pool or lake back in the day. Being that camping furniture production was also a seasonal business, producing aluminum Christmas trees in the off-season was a perfect fit. PECO ran 2 production shifts.

A day at PECO. Image courtesy of the Ashkouti Family

PECO has the prominence of belonging among The First Families of Aluminum Trees, as well as in the category of Manufacturers with Aluminum Roots.

Founder Joseph A. Ashkouti was a noted engineer, as was Joe Warren, who served as Production Manager in the aluminum tree era. During interviews, Warren revealed his steel-trap mind in recalling the aspects of tree production. When asked what he thought of aluminum Christmas trees during the production era, Joe Warren did not skip a beat when responding, “How many I could make in a day!” Spoken like a dyed-in-the-wool production manager.

Joe Warren’s Fun Facts on PECO Production:

WINDING

Rods were inserted into a wooden rack with slots, and glue was then applied. Sewing machine motors were again employed to wind the rods using a foot pedal.

The women- and it was always women- who wove the webbing for the aluminum chairs became aluminum branch winders in the off-season.

PACKING

Once in sleeves, branches were loaded on a conveyor. An electric eye counted the branches, stopping at the correct count for the tree being packaged.

2-TONE TREES

PECO produced a Silver-Gold and a Silver-Green.

PECO Silver-Green

An inking machine was used to dye one side of the aluminum. The rolls of aluminum were passed through a drum of quick-drying ink. According to Joe Warren, PECO never inked both sides of the aluminum to produce a solid green or solid gold tree.

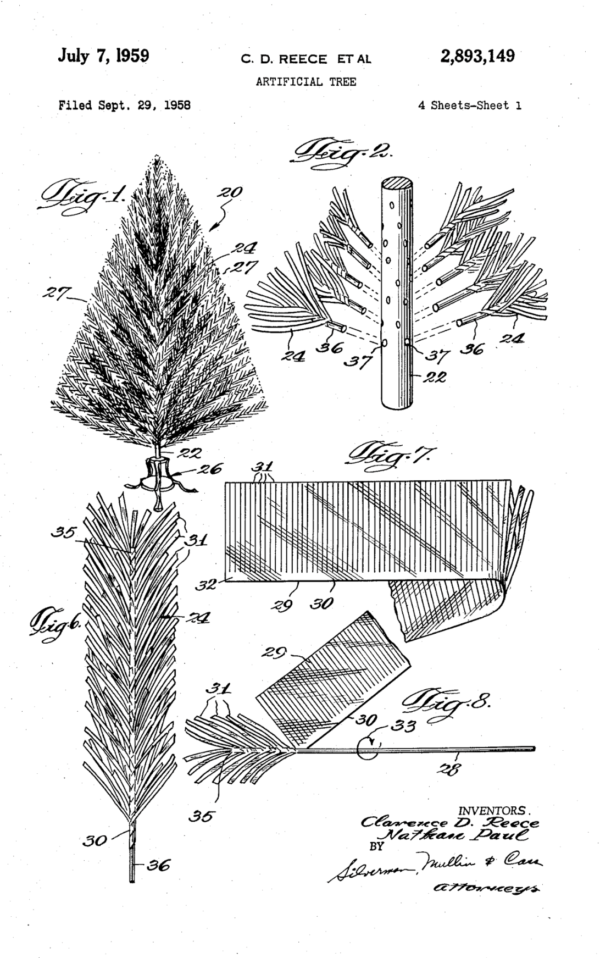

PATENTS

PECO licensed under the Reece Paul patent 2,893,149

Courtesy of the United States Patent and Trademark Office

DISTRIBUTION

Joe Warren named K-Mart and Federated Department Stores as 2 main retail outlets for PECO.

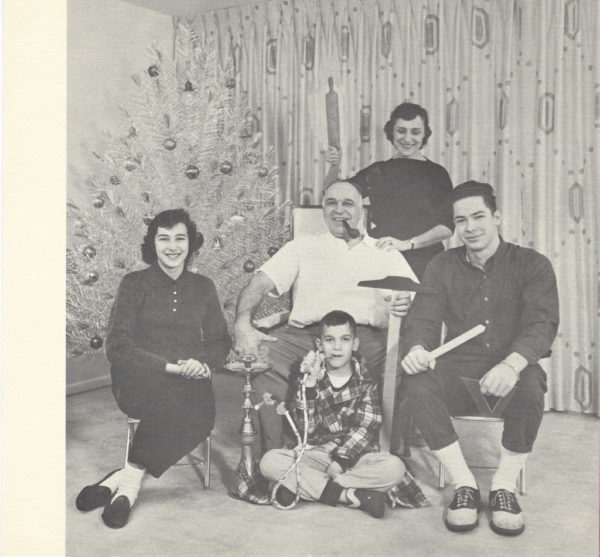

Family

Joseph and Evelyn with children Diane, Jerry and Albert. Courtesy of the Ashkouti Family.

Founder Joseph A. Ashkouti (there are many Joes and Josephs in the family. Founder Joseph will be referred to hereafter as Joseph A.), along with wife Evelyn, ran a family business. Production Manager Joe Warren was the first cousin and Godson of Joseph A.

Evelyn Ashkouti. Note the unusual black-inked PECO box. Image courtesy of the Ashkouti Family

Being Lebanese Maronite Catholics, the Ashkoutis were part of a tightly-knit family and community. PECO’s production manager, Joe Warren, the first cousin and Godson of Joseph A., graciously (and somewhat suspiciously) granted an interview at his home in Tybee Island, Georgia.

Joe Warren in the modern day.

Joe W. describes Joseph A. as his idol growing up. He spoke of Joseph A. with great reverence and pride, and readily conveyed the many achievements of his Godfather: NYU graduate in aeronautical engineering, designer of major aircraft parts for Grumman Aircraft of Long Island, author, and family man. Evelyn wanted to live close to her parents, so subsequently Joseph A. went to work at the Bell Bomber plant in Marietta, Georgia, and the Ashkouti family took root in the south.

The Atlanta Constitution Dec. 12, 1942

Joe Warren describes Joseph A. and Evelyn as “a very good complement to one another.” He disclosed the story of Joseph A. being a day late to his Christmas Day wedding! Bride Evelyn was kept waiting due to Joseph A. being stuck in a snow storm in New York. The happy couple were wed on December 26, 1942.

Joseph A. Ashkouti was a philanthropist. In New York, he was a member of the historic and prestigious St. Nicholas club. He gave generously to his church, and held the position of Georgia Coordinator of St. Jude. Grandson Joe Ashkouti recalls that Danny Thomas performed at a fundraiser in the Ashkouti home. In his college days at Georgia Tech, Joe Warren sold Krispy Kreme donuts on the street as a fundraiser for St. Jude.

Hallmarks of PECO

QUALITY

PECO’s approach to design and manufacturing was quality first! Quality dictated the price point, not the other way around.

POLES

PECO poles were painted silver, made with 3 branches per row. Each row was drilled at a different angle to give the tree a signature look. The drills were powered by a sewing machine motor, with a chuck attached to hold the bit. The bits had to be between 15-18” long.

BOXES

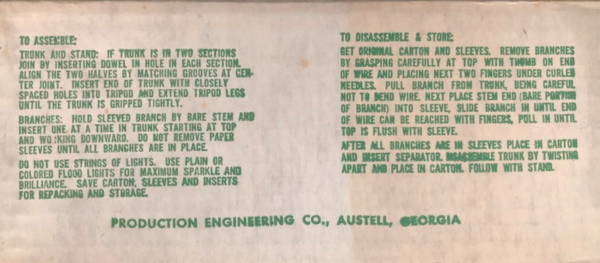

Rather than an included instruction sheet, PECO printed their instructions right on the box. This streamlined approach is a finite example of how things worked at PECO.

Do you have a PECO tree not in the gallery of The Aluminum Forest? We want to hear from you! If you contribute a photo and we use it on the site, we would love to bestow a photo credit!

Please enjoy the Gallery of Peco!