Branch Problems

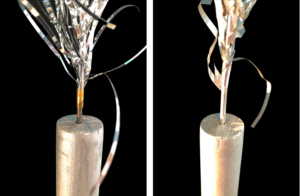

Aluminum winding loose from rod end

This is common. In fact, it apparently was a common problem even back in the day, as very often aluminum tree branches will have old, yellowed, brittle cellophane tape at the rod bases.

L: old yellow cellophane. R: loose foil.

Old tape is preferable to new tape for a couple of reasons. Firstly, it is usually easier to remove due to being brittle. Secondly, newer tape jobs tend to be bulky and cloudy. To address this situation, run, don’t walk, to your local hardware store and buy some metal repair tape.

Available at your local retailer

One roll will last you a lifetime of tree repairs. Hold the rod with one hand and spin the rod until the winding is tight. Use small thin strips and apply using a downward spiral. Employing the least amount required to get the job done will achieve the best results. So easy, anyone can do it!

Repaired with aluminum tape

If you spin the rod and the winding does not tighten, you have 1 of 2 problems: either the winding has separated somewhere along the length of the branch, or the winding has separated from the top end of the branch. This type of problem would fall into the ‘advanced repair’ category and requires some experience and finesse.

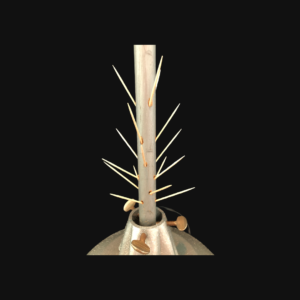

Branch count vs. holes in pole

If there is any question as to the completeness of a tree, there is a quick and easy hack for both buyers and sellers. Pole holes can be counted by placing toothpicks in the pole holes and comparing the number of picks used to the number of branches present. Especially with taller trees, this method is a time saver as compared to a complete tree assembly.

Taper tree arrives out of order

One can only hope it arrives on a rainy day with nothing pressing to do. The work is arduous but the rewards are great. Revlis is by far the most common case. A trained eye can spot a Revlis that is assembled out of order, even from online photos. Even if assembled correctly for a listing, a Revlis invariably will arrive with some branches having popped out from the cardboard pallet base. The solution is a labor intensive sorting of the branches according to length. It can be exhausting work, darlings!

Coding the rod ends using incremental indicators is advisable. A number of methods can be employed to code these trees. The best solutions involve using a marker or indicator, such as a little rubber band on the rod end. Don’t forget to make a legend reflecting your coding. The only known company to factory-code their taper trees is Carey-McFall.

Scrunched needles

This problem is very common and there are methods to restore the needles. A lot of time and patience is required to address this issue. This aspect of restoration is not for everyone. But for some, it is an art form. For now, I defer to aficionados of this type of restoration. There are methods using a toothpick, methods requiring full removal of the windings from the rod, and hand-tooling methods. All of this falls into the advanced level of tree restoration. If one has the time, patience and ability, a marginal tree can be transformed into a stunner. The hack in this case is to hide the worst-case branches to the back of the tree for display.